The team describes the use of bioreactors for ligament tissue engineering applications

The aim of this study was to design, develop and validate a simple, compact bioreactor system for tissue engineering. The resulting bioreactor was designed to achieve ease-of-use and low costs for automated cell-culturing procedures onto three-dimensional scaffolds under controlled torsion/traction regimes.

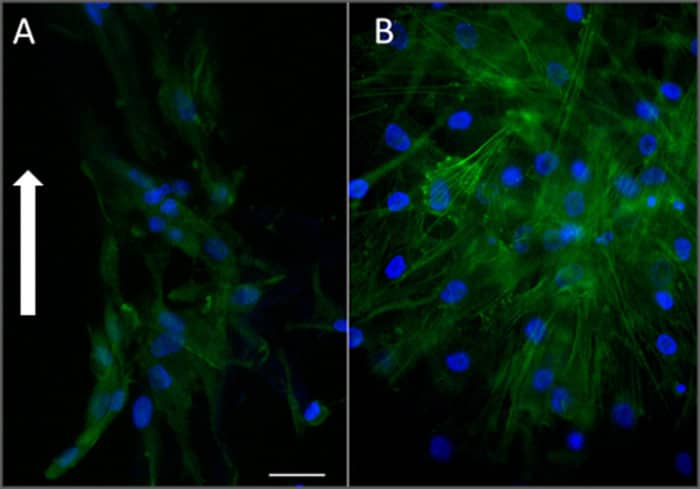

Highly porous poly-caprolactone-based scaffolds were used as substrates colonized by fibroblast cells (3T3 cell line). Constructs were placed within the cylindrical culture chamber, clumped at the ends and exposed to controlled sequences of torsional stimuli (forward/back-forward sequential cycles of 100 degrees from neutral position at a rate of 600 degrees/min) through a stepper-motor; working settings were defined via PC by an easy user-interface. Cell adhesion, morphology, cytoskeletal fiber orientation and gene expression of extracellular matrix proteins (collagen type I, tenascin C, collagen type III) were evaluated after three days of torsional stimulation in the bioreactor system.

The 3D bioreactor system was validated in terms of sterility, experimental reproducibility and flexibility. Cells adhered well onto the polymeric scaffolds. Collagen type I, tenascin C and collagen type III gene expression were significantly up-regulated when cells were cultured under torsion in the bioreactor for three days. In conclusion, we have developed a simple, efficient and versatile 3D cell-culture system to engineer ligament grafts. This system can be used either as a model to investigate mechanisms of tissue development or as a graft manufacturing system for possible clinical use in the field of regenerative medicine.

S. Scaglione, B. Zerega, R. Badano, U. Benatti, M. Fato, R. Quarto (2010): “A three-dimensional traction/torsion bioreactor system for tissue engineering” Int Journal of Artif Organs

All Resources

Never stop learning!

Check publications from the team, protocols, and useful information to boost your research and get into organ on chip technology!